Water System Selection - by Nelsen Corporation

Water system selection

In selecting the proper water system for a given installation, facts about the water source as well as the water requirements must be considered. Assuming the water source is a well, the following information is needed:

- Well size – (diameter)

- Depth to pumping level

- Well capacity (maximum pumping rate it will sustain)

- Elevation and total length of piping

- Amount of capacity required

- Amount of pressure required

Well size

The inside diameter of the well must be known since it may be the determining factor as to the type of pump which can be used. Submersible pumps require well at least 4 inches in diameter. Packer type jet systems can be installed in wells with diameters as small as two inches.

Depth-to-pumping level

The depth to the water level at maximum drawdown determines the type of pump that must be used. For depths of 25 feet or less, at or near sea level, shallow well “suction lift” type pumps are adequate. Each 1000 feet of elevation above sea level reduces the shallow well depth limit by one foot.

For example, the maximum practical suction lift in the Denver area, which is 5000 feet above sea level, would be 25 minus 5, or 20 feet. For lifts greater that the maximum suction limit, deep well type pumps, which have a pumping mechanism in the well, are required. The pumping level may be estimated from the well drillers test log.

Well capacity

The maximum pumping rate the well will sustain must be known to assure that the capacity of the water system selected does not exceed that rate. As in the case of pumping level, well capacity may be obtained from the well drillers log.

Elevation and total length of piping

The elevation the total length of piping are required to compute the pressure drop in the system. This computation is made by adding the elevation to the drop caused by pipe friction. Pressure drop due to friction is calculated by using the friction loss tables.

Amount of capacity required

In determining the required capacity of a water system, it is important to provide for the peak demand rather than for the average use rate. A good rule of thumb to follow is to allow for one gallon per minute of pump capacity for each household outlet. For farm water systems, adequate water

must not only be provided for household purposes and animal drinking, but for cleaning and fire protection as well. Average water consumption per day for various animals is shown in Table 1. The pump selected should have sufficient capacity to pump the entire daily requirement in two hours. As an

example, assume a farm with 20 milk cows, 100 hogs, 500 chickens, two milk houses and eight household outlets.

The daily water consumption of the animals would be as follows:

| Milk cows | 20 x 35 | 700 |

| Hogs | 100x4 | 400 |

| Chickens | 500/100x6 | 30 |

| Total Daily Usage | 1,130 | |

| Pumping Capacity for 2 Hours (120 minutes) | ||

| Period | 9.4 G.P.M. | |

| Milk House Outlets | 2 | |

| Household Outlets | 8 | |

| 19.4 G.P.M. |

A 19 gallon per minute pump will provide sufficient water for the farm needs, including fire protection. The Well Capacity should be compared to the Pump Capacity to make sure the well can sustain a pumping rate of 19 gallons per minute. If it will not, an extra large pressure tank, or a two-pump system with storage tank will be required.

Table

1. ave. water consumption for home/farm use

A. Home Use

For overall daily consumption, checks of families of

various sizes in different parts of the country indicate 100

gallons per day per person is a very good average.

| Outlet | Total gallons | Flow rate |

|---|---|---|

| Per usage | (GPM) | |

| Shower | 25-60 | 5 |

| Bathtub | 35 | 5 |

| Lavatory | 02-Jan | 4 |

| Toilet - flush | 07-Mar | 4 |

| Kitchen sink | 5 | |

| Laundry tub | 7 | |

| Washer automatic | 30-50 | 5 |

| Dishwasher | 20-Oct | 2 |

| Water softener | up to 150 | 7 |

| Garden hose 1/2" | 3 | |

| Garden hose 3/4" | 6 | |

| Sprinkler lawn | 6-7 | |

| B. Farm use | Gallons per day | |

| Horse, Mule, Steer | 12 | |

| Dry cow | 15 | |

| Milking cow | 35 | |

| Hog | 4 | |

| Sheep | 2 | |

| Chickens/100 | 6 | |

| Turkeys/100 | 20 | |

| Fire | 20-60 GPM |

Based upon a study of over 20 sources by the Water Source and Use Subcommittee of the Water Systems Council. Values given are average. They do not include the extremes.

Amount of pressure required

Discharge Pressure of the pump must be sufficient to balance Pumping Depth plus Pipe Friction plus Elevation plus tank pressure. Water system pressure tanks usually operate within the pressure range of 20 to 40 lbs. per square inch.

However, recent high demands for pressure, caused by automatic

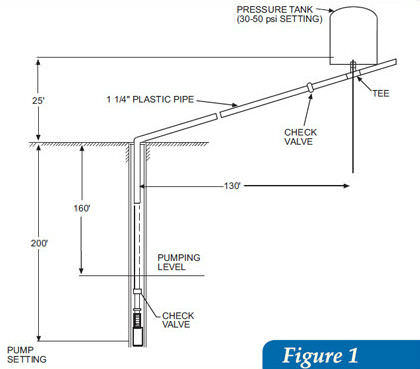

washers and other appliances, have resulted in many systems being set for 30 – 50, or even 40 – 60 ranges. An example for determining the required discharge pressure for a typical submersible pump system is shown below. Assume a pumping rate of 12 gallons per minute.

- Convert all measurements to the same units. In this case, we will change tank pressure from pounds per square inch to equivalent feet of head by multiplying by 2.31, as shown in the engineering formulas on Page 416. Using 40 p.s.i. as the average tank pressure, 40 x 2.31 = 92.4 feet of head.

- Compute pipe friction by using the tables on Pages 413 – 415.

| (1) 1-1/4" Plastic Tee | 1 x 3 | 3 ft Equivalent Pipe Length |

| (2) 1-1/4" Check Valve | 2x7 | 14 ft Equivalent Pipe Length |

| (1) 1-1/4" Elbow | 1x1.7 | 1.7 ft Equivalent Pipe Length 18.7 ft Total for fittings |

Pressure drop from pipe friction

(200* + 130 + 18.7) x 2.33 100 = 8.1 ft

Total Dynamic Pumping Head

8.1 + 160* + 25 + 92.4 = 285.5 ft

Note: While total pipe length must be used to compute pressure loss due to pipe friction, only the distance to pumping levels is included with elevation in the summation for total pumping head.

Pressure at pump discharge, in lbs. per square inch

285.5 = 123.6 PSI 2.31

Total lift, exclusive of tank pressure

285.5 - 92.4 = 193.1 ft (round off to 200 ft)

To select the proper submersible pump for this installation, first choose the appropriate table in the catalog, which would be for a 12 gpm rated pump. Follow the 200 ft Depth-to-Water column down until a pump is found that has the entire desired pressure range covered. The 1 hp model meets the required performance. Now check the performance at 200 ft. and 60 P.S.I. pressure to make sure that the pump will generate sufficient pressure to actuate the pressure switch at the cut-out point with at least 10 psi to spare.

Note: In selecting jet pumps, either shallow or deep well type, the friction loss of the piping in the well is included in the performance tables. Therefore, only elevation and friction loss outside the well need to be calculated. If the offset (horizontal distance between the pump and the well) is greater than 35 ft, the offset piping should be increased one pipe size.

Tank selection

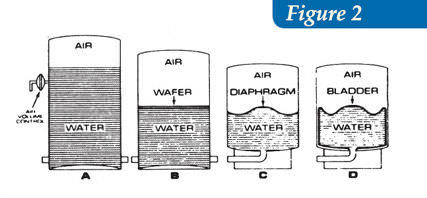

Selection of the proper tank completes the water system. Pressure tanks used with water systems are of the hydropneumatic type. Compressed air in the tank acts as a giant spring to provide a pressure range, between pump stops and starts, during which a reasonable amount of water can be withdrawn. This is necessary to prevent the pump motor from cycling too often, and to provide s smooth flow of water to the outlets, without water hammer.

Types of pressure storage tanks. Figure 2A shows plain steel tanks; Figure 2B, the plain steel tank with floating wafer; 2C, the diaphragm tank; 2D the bladder tank.

Contact:

George Hogg

WTC

Email:

info@waterbygeorge.ca

Cell:

780 871 9283

Phone:

780 809 2256

Postal Address:

PO Box 12699

Lloydminster, AB T9V 0Y4